How elastic bonded diamond tools optimize precision machining

When the hardest material in the world and soft plastic come together, the result is tools with very special grinding properties. We are talking about elastic bonded diamond grinding wheels. These show their strengths during finishing and ensure the perfect finish. Innovative processes such as these are necessary because the manufacturing industry faces the challenge of producing increasingly complex and precise components from resistant materials. Conventional production methods often reach their limits here, especially when the surfaces are so fine that they require particularly sensitive processing. At the GrindingHub trade fair, organized by the VDW (German Machine Tool Builders' Association) in Stuttgart from May 5 to 8, 2026, visitors will learn more about innovative grinding techniques for achieving the highest surface qualities.

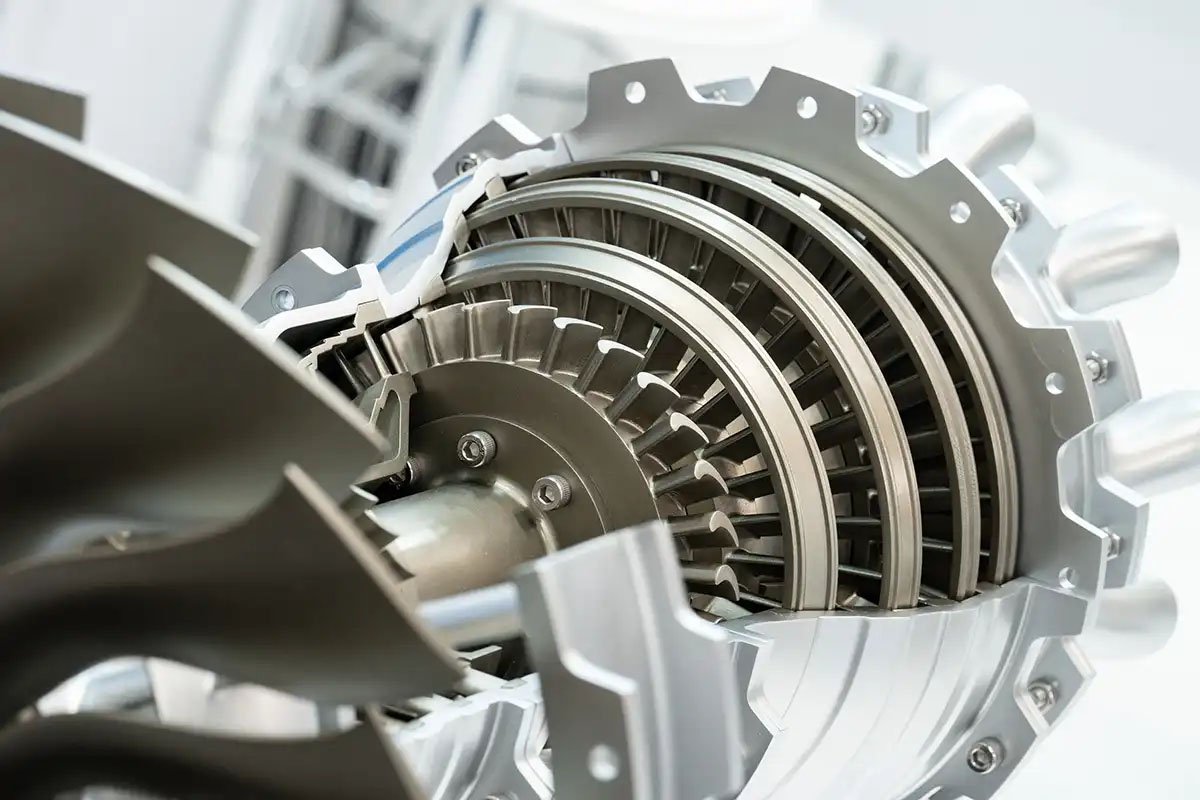

For demanding finishing and polishing processes

Elastic

grinding and polishing tools are used in a wide variety of industries.

In metalworking, they refine surfaces ranging from the finest surgical

instruments to heavy-duty turbine blades. These tools can be used to

accelerate manufacturing processes and increase cost-effectiveness and

sustainability in production. "Our

elastic bonded diamond tools demonstrate their strengths wherever

extremely hard materials such as carbide need to be machined with

precision," says Jens Meiberg, Head of Technology Development at

GrindingHub exhibitor Artifex Dr. Lohmann GmbH & Co. KG, a

specialist in elastic grinding and polishing tools based in

Kaltenkirchen near Hamburg. "They

achieve their maximum effect particularly in applications where

extremely fine surfaces, even mirror finishes, are required,"

says Meiberg. This makes them ideal for demanding finishing and

polishing processes. According to Meiberg, Artifex is currently focusing

on the machining of carbide drilling and milling tools to improve

cutting edges and achieve more efficient chip removal from cutting

tools.

Greater efficiency and reduced overall costs

Technically

optimal surfaces are one thing, cost-effectiveness is another. In

industrial practice, it ultimately comes down to the cost-benefit

analysis for the user. In other words: When does the improved surface

quality justify the higher cost? "Studies show service life improvements of more than 50 per cent compared to unprepared tools," says Artifex manager Meiberg. Combined

with faster chip flow and greater chip volume, users achieve

significant cost and service life advantages. Machining with elastic

bonded diamond tools significantly improves the surface quality of the

machined workpieces. In practice, this optimization leads to noticeably

longer service life for subsequent tools and more stable and reliable

process behavior. Users benefit from greater efficiency and reduced

overall costs," says Meiberg.

Delicate machining for delicate surfaces

Some

surfaces are so delicate that they must be machined with extreme care.

As the Head of Technology Development at Artifex explains, flexibly

mounted diamond particles achieve "non-contour-changing glossy surfaces"

by cutting topological material peaks. The homogeneously distributed

abrasive medium bounces back and forth in the bonding matrix. Put simply

and in layman's terms: the soft mass gives way slightly, so that the

grains wobble slightly when rubbed instead of scratching firmly.

Therefore, the surface is only gently smoothed and polished, rather than

aggressively removing material or changing the shape. In other words:

the smarter grinding wheel gives way. "The

pressure and speed parameters of the process pose the greatest

challenge in preventing grain break-outs from this newly developed soft

bond," says Meiberg. The surface quality can be achieved

reproducibly throughout the entire life cycle of the disks. Thanks to

the tool change options in the machine, machining is carried out in a

single clamping and not through downstream processes. According to

Meiberg, Artifex's in-house Research and Development Department ensures

the continuous advancement of diamond tools – particularly with regard

to new carbide alloys and modern carbide tools.

Scope for basic research down to the nanometer range

There

is still plenty of scope for basic research at universities in the

micro- and nanometer range. This also applies when using flexible

precision machining tools in the finishing of structured surfaces. Dr.

Monika Kipp, who heads the Grinding Technology Department at the

Institute of Machining Technology at the Technical University Dortmund,

is intensively involved in this topic. "One example of the use of flexible precision machining tools is the finishing of structured surfaces,"

says Kipp. If these are produced by milling, for example, micro-burrs

may occur. In order to remove these without significantly altering the

structure and at the same time improving the surface finish, the tools

must be highly adaptable and only a very small amount of material should

be removed. "To achieve this goal, our research focuses on the fundamental process behavior of flexible diamond tools,"

says the scientist, who was recently awarded the Otto Kienzle

Commemorative Medal by the WGP (Scientific Society for Production

Engineering).

Perfect choreography

When

machining highly sensitive surfaces with flexible tools, it is

essential to know exactly how the tools and material interact. "In

order to avoid unwanted contour changes in precision machining with

elastic bonded diamond grinding wheels or other flexible grinding tools,

it is essential to understand the basic process interactions,"

says Kipp, summarizing the key challenge. This includes, for example,

coordinating the process parameters and the bonding strength or

flexibility of the tools and thus the local contact situation. In

addition, according to the scientist, targeted adjustments to the

process control with regard to the kinematics of the procedure could

also be effective. In layman's terms, you can imagine it as

choreography. How fast does the grinding tool move? How fast is the

workpiece moving? At what angle or pattern do the grains strike the

surface? How often does a single grain engage with the material? For

optimal results, perfect coordination is essential.

Three factors: contact pressure, contact time, grain size

The surface quality in precision machining depends, among other things, on the local contact situation, says Kipp. "When

it comes to process design, a distinction must be made in terms of the

objective: whether the aim is to achieve the lowest possible roughness

or whether functional surfaces with structural or contour elements need

to be reworked," explains the researcher. Flexible abrasive tools

can be used for corresponding applications. Material removal and thus

the surface finish can be controlled by adjusting the contact pressure,

contact time, and grain size, among other factors.

The grinding gap is a mystery

Applications

at the limits of what is technically possible and economically viable

therefore open up a wide field for industrial and academic research.

Because the saying among experts still holds true: "The grinding gap is a

mystery." This phrase suggests that practitioners and researchers still

need to shed light on the deepest physical and process engineering

secrets of grinding in order to technically optimize industrial

production processes and make them more efficient and sustainable.

Industriale.it certification

Industriale.it certification