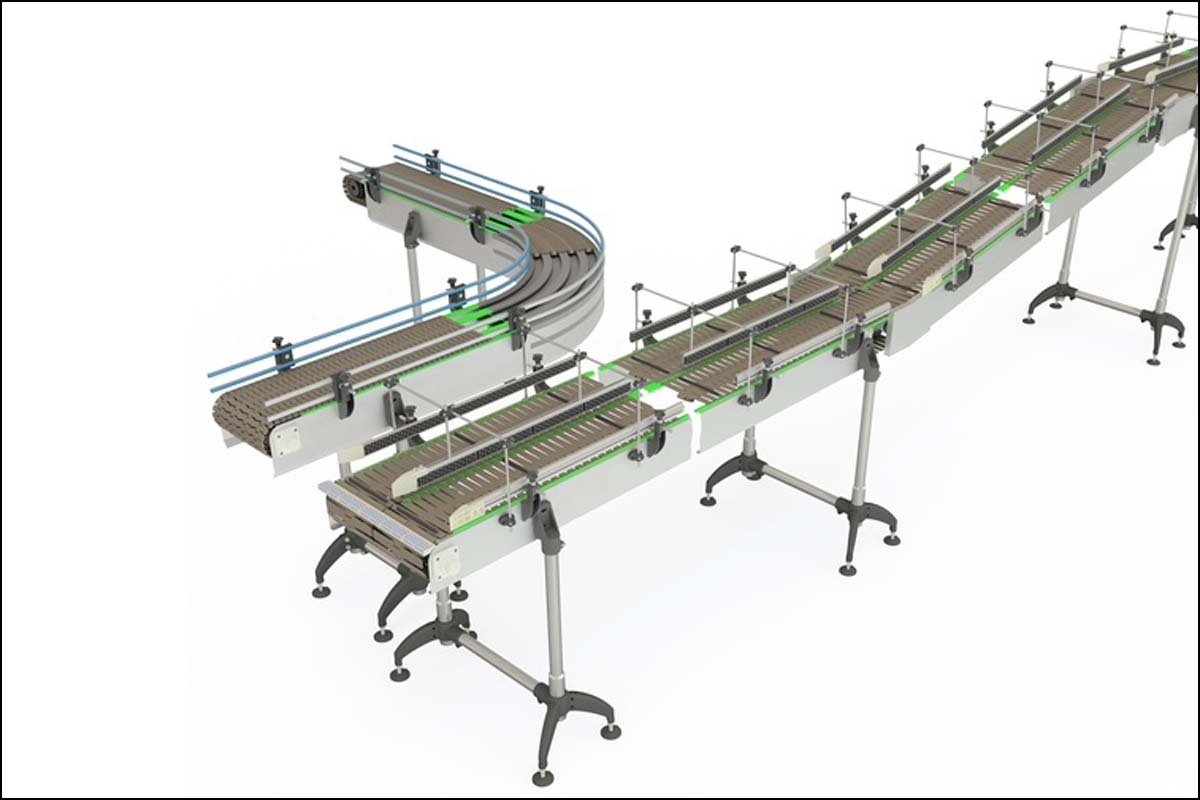

A wide variety of product sizes, ever-changing shapes, materials, and challenging environments: today's conveyor systems are subjected to a great deal of pressure. KIPP's new modular system offers the necessary scope to meet precisely these challenges. Adjustable lateral guides enable quick and easy adjustment of the conveyor belt and damage-free transport. Support elements provide the necessary stability. The result is a versatile and flexible system that meets every requirement for ease of use and process reliability.

If a product is not running steadily on a conveyor belt, there is rarely just one cause. Often, small deviations in the guidance or insufficient support from the structure cause problems. With its new modular system of components for conveyor systems, KIPP offers a modular solution that adapts to a wide variety of conveyed materials and environments: from the food and packaging industries to automation technology.

Individual adjustment for a wide variety of conveying scenarios

Adjustable lateral guides and support components such as tube connectors or support elements are indispensable parts of modern conveying technology. They ensure precise alignment and safe guidance of the conveyed material, adapting to its size, shape, and material. This allows different product series to be conveyed without time-consuming reconfigurations.

KIPP's new lateral guides are available in a lightweight, corrosion-resistant plastic (PE-UHMW). PE-UHMW ensures minimal friction between the guide and the product, thus enabling extremely gentle transport of sensitive products. The modular system includes, in addition to the lateral guides, various types of supports and clamps. Single or double clamps provide adequate support, while height-adjustable flat bars allow for millimeter-precise adjustment. KIPP also offers suitable clamps for use with round stainless steel profiles.

Stability for the entire system

In addition to lateral guides, the KIPP modular system includes support elements that stabilize and secure the conveyor structure. The components prevent deformation of the structure and ensure precise alignment of the conveyor belt. The tube connectors of the support elements are adapted to the standard diameters of 48.3 mm and 60.3 mm (DIN EN 10220) and allow for stable cross-connections and modular adjustments. Depending on the version, the load capacity varies between 1.5 kN and 9.6 kN. The range includes two- and three-legged base elements, T-connectors, and support heads. All components are made of durable, corrosion-resistant materials.

One system, many possibilities

KIPP's new modular system is designed so that users can easily integrate components into existing systems or configure them for new projects. The modular structure allows individual components to be replaced or expanded as needed. This allows conveyor systems to be specifically adapted to changing products or process conditions, without compromising on safety and conveying quality.

Industriale.it certification

Industriale.it certification