Heat treatment is crucial in numerous industrial sectors, from glass to metals, from semiconductors to photovoltaic panels. These processes require careful management of temperature zones, through precise control of the current and power of the electric heating elements. The increasing digitalization of systems, driven by Industry 4.0, also requires devices capable of rapidly communicating with higher-level automation systems.

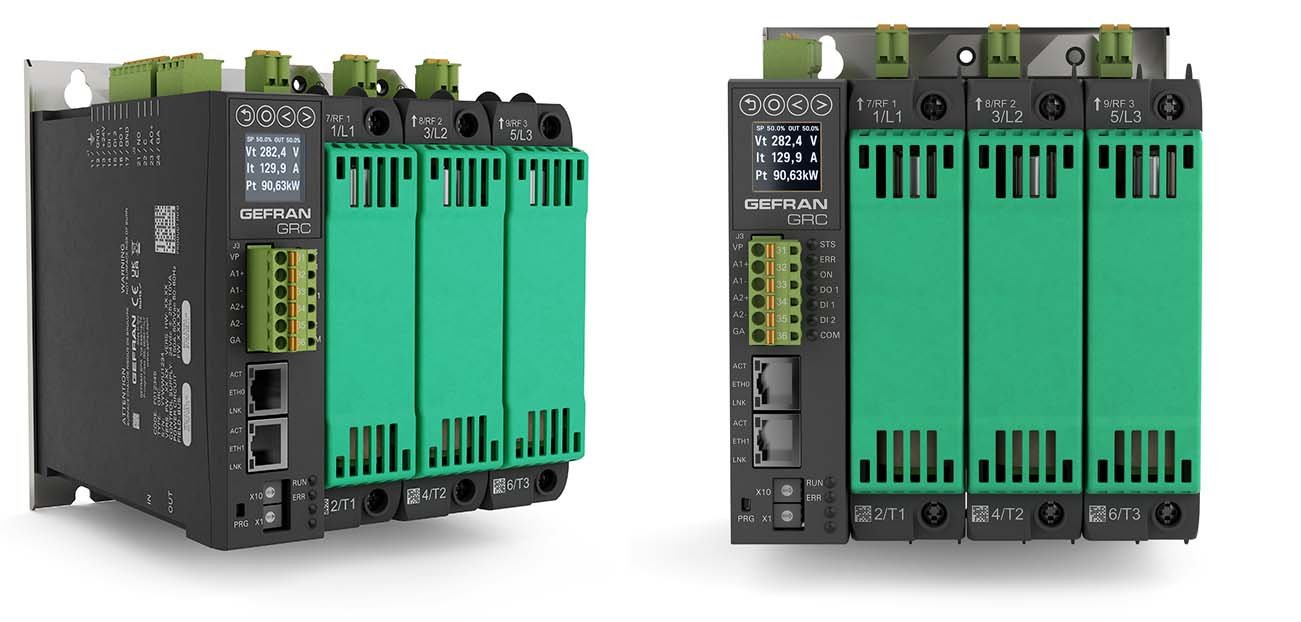

In response to these needs, Gefran presents GRC, the new series of intelligent and compact power controllers. Designed to offer high performance in industrial electric heating, they combine power, precision, and advanced connectivity via the main communication protocols.

GRC introduces new standards of scalability in the control of electric heaters. The series is modular and available in single-, two-, and three-phase configurations, with currents from 25 A to 150 A, thus adapting to linear and non-linear resistive loads for high temperatures. The compact size, combined with integrated fuses, allows for optimizing space in electrical panels, facilitating the design of more compact systems. Accurate current and voltage readings are another strong point. Thanks to integrated feedback algorithms, GRCs maintain stable power and current even in the presence of electrical disturbances, essential in critical processes such as semiconductor production or flat glass treatment.

Advanced connectivity completes the features of the series. All devices are native Ethernet and offer two physical ports for immediate access to data, without the need for additional cards or gateways. The integrated WebServer allows complete control of diagnostics and alarms through easy browser access from any device and remotely. Furthermore, the front LCD display allows for real-time monitoring of system performance, allowing timely intervention in the event of anomalies and optimizing operational continuity.

With the dedicated Gefran GF_eXpress software, installation, configuration, and maintenance are even faster and more intuitive. Thanks to a smart interface, designed to guarantee intuitive diagnostics and support efficient and customizable production processes.

"With GRC, Gefran's GRx platform is enriched with compact and functional devices, designed to meet complex application needs. The expansion of the available current range, already envisioned in the launch roadmap, demonstrates Gefran's commitment to creating flexible and scalable solutions," states Guido Zini, Power Controllers & SSR Product Manager at Gefran. "Innovation continues: with the expansion of the range scheduled for February 2026, advanced features in terms of digitalization, efficiency, and sustainability will be introduced."

Industriale.it certification

Industriale.it certification