Measure torques cost-effectively, reliably, and maintenance-free.

Flange Torque Sensor with Optical Data Transmission

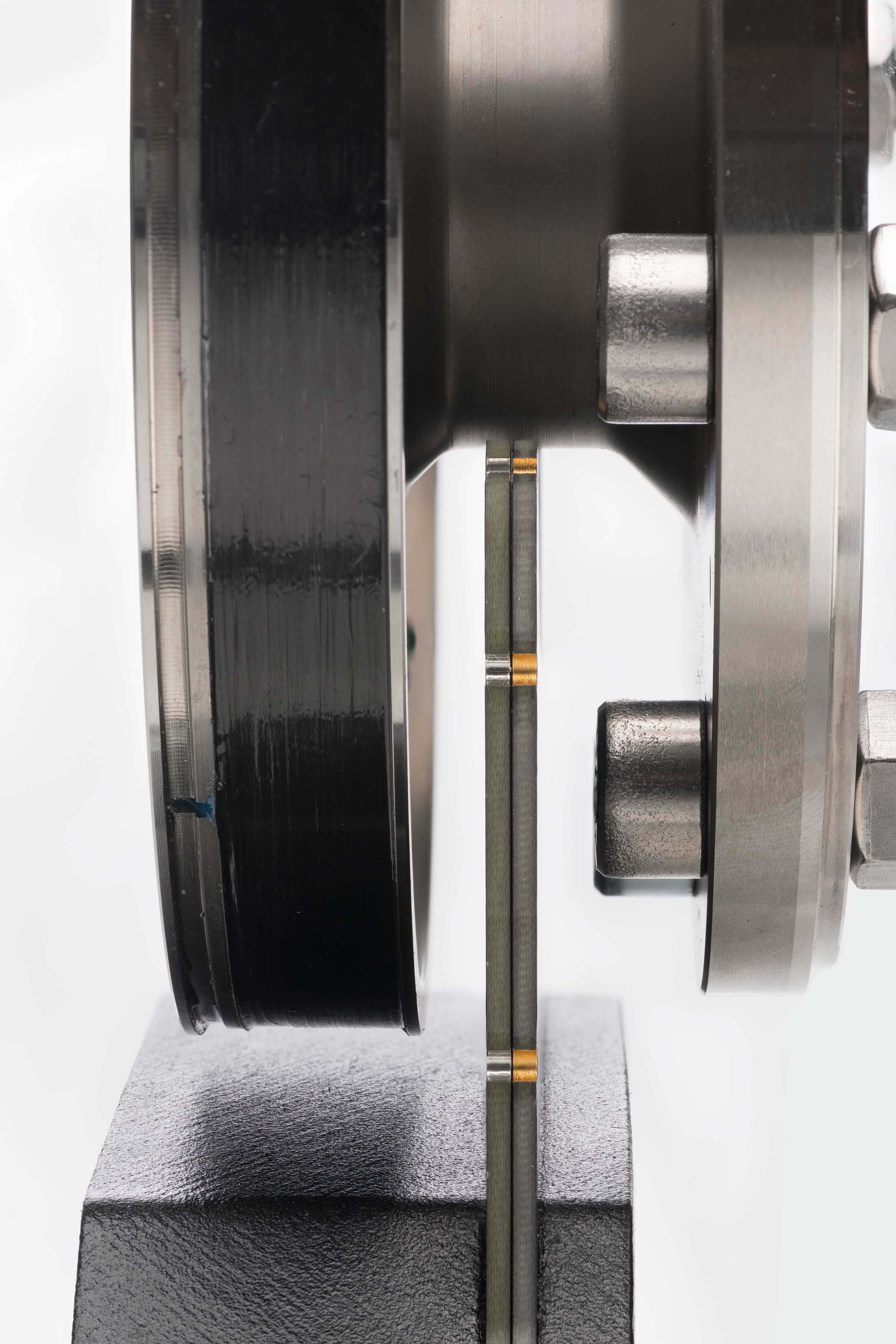

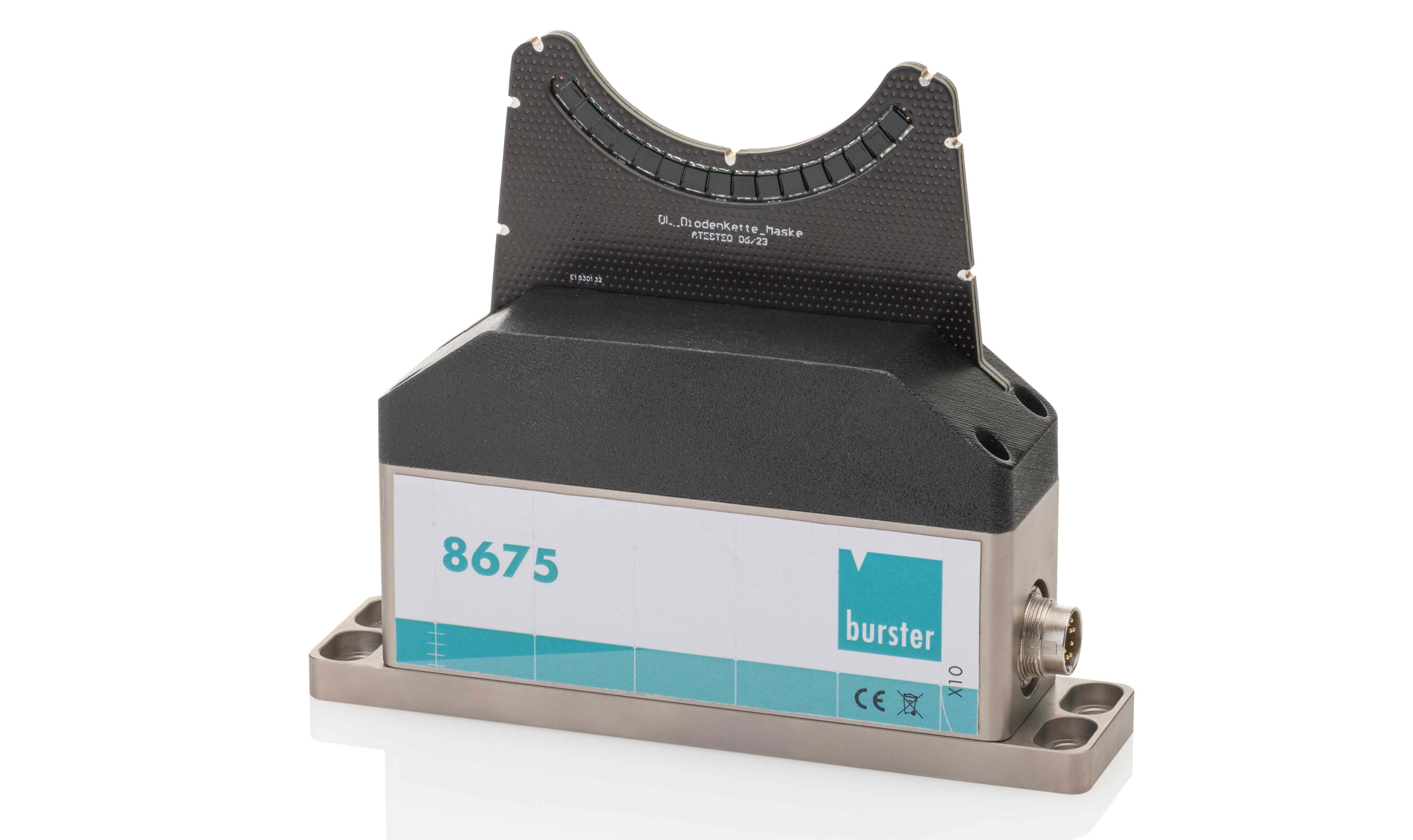

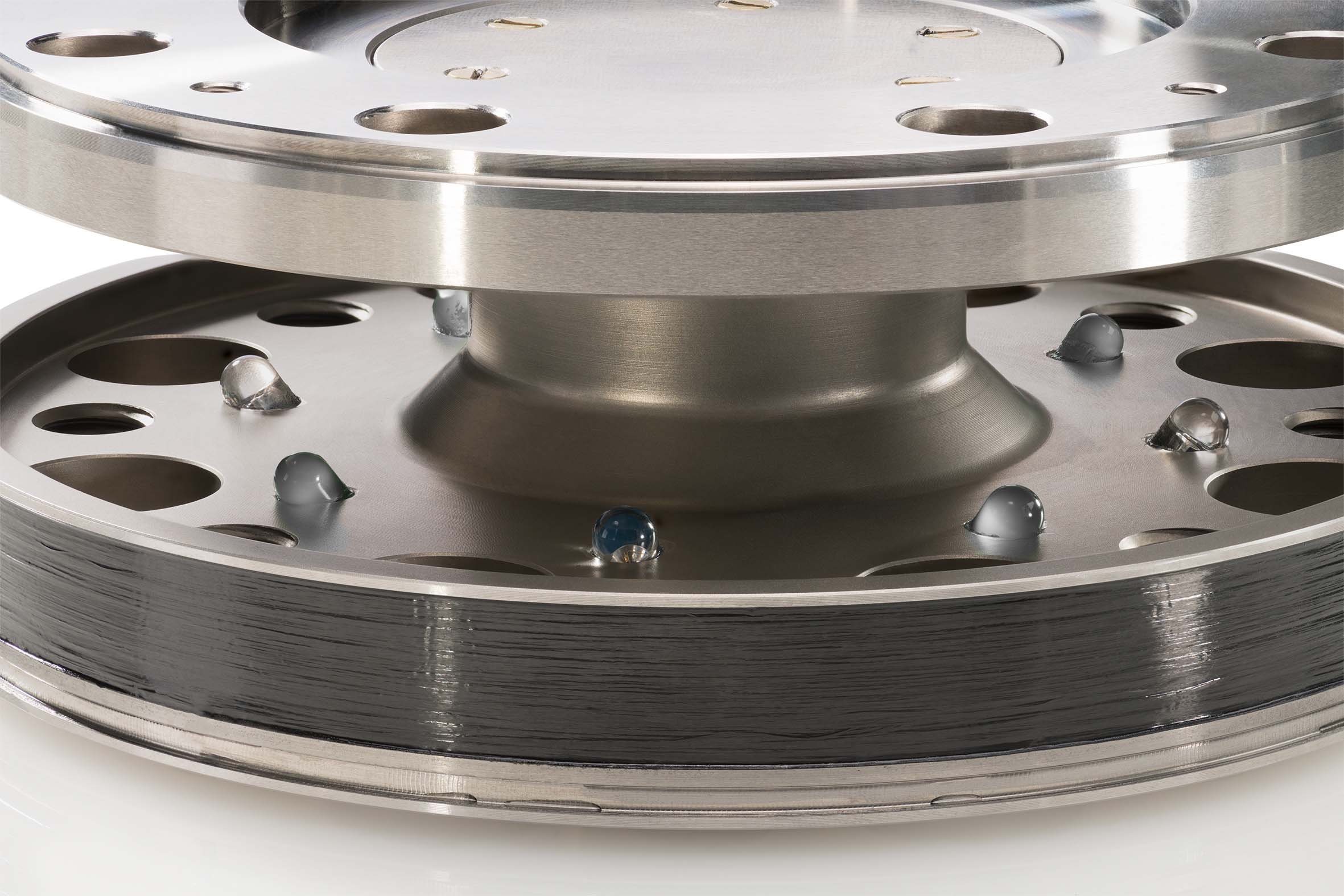

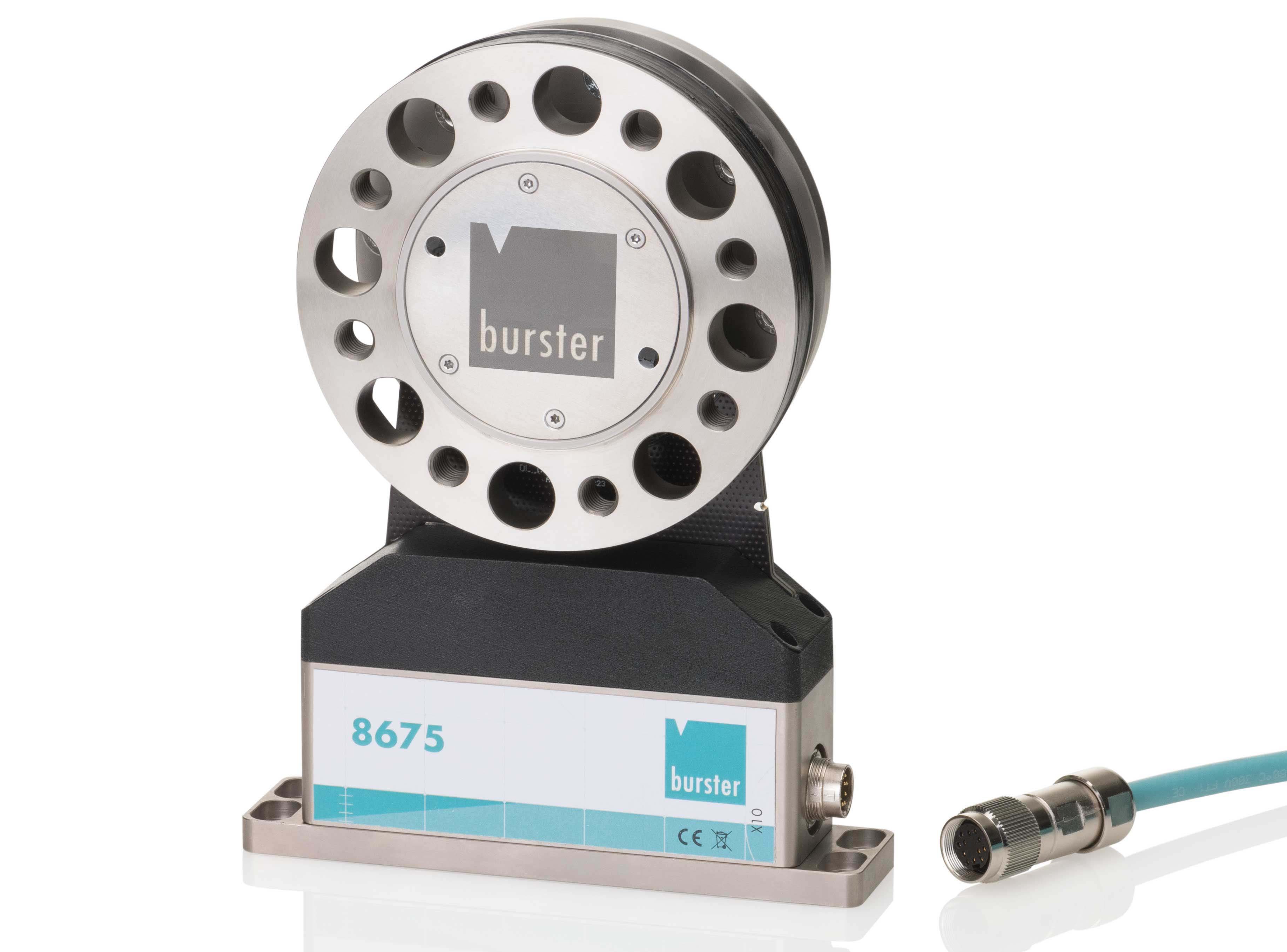

Burster measurement specialists have developed a cost-effective flange torque sensor with inductive power supply, which is also immune to EMC interference thanks to optical data transmission. The model 8675 sensor consists of a flange rotor with DIN mounting and a stator. This supplies power to the evaluation electronics for the strain gauge in the rotor, receives digitized measurement data in the rotor via non-contact IR LEDs, and transmits torque even when stationary. This eliminates the need for slip rings and bearings that are subject to wear, and the sensor is completely maintenance-free. Depending on the version, the measurement range is from 0 to 100 Nm or from 0 to 5000 Nm. The sensor is optimized for the vast majority of applications in mechanical and plant engineering, offering an accuracy of 0.1%. It is the ideal solution for those who require reliability, long life, and zero maintenance, without the need for extremely high precision. Typical applications include quality monitoring of electric motors and gear units, test bench construction, and research and development.

This practical sensor is ideal for a wide range of applications.

Its extremely compact design allows for seamless integration even in confined spaces. IR optical transmission offers a distinct advantage for international use, eliminating the need for complex approval procedures for different markets. This not only reduces costs but also shortens delivery times. The torque sensor is available as standard with an analog output (0-5 V, 0-10 V, ±5 V, ±10 V) and a frequency output (RS422, 24 bit), as well as a USB connection for configuration. A test and calibration protocol is included. Standard and special calibration certificates, including accredited ones, are available from the burster calibration laboratory and can be ordered directly if needed. The temperature range is -20°C to +85°C and the maximum operating torque is 300% of the rated torque.

Burster provides measurement technologies ranging from individual sensors to system solutions. Its customers are primarily in mechanical and plant engineering, automation, the automotive industry and its suppliers, electrical and electronic engineering, and the chemical industry. The product range includes measuring instruments and testers, as well as standard sensors for mechanical and electrical measurements, such as load cells, pressure, torque, and displacement sensors, milli- and megohmmeters, and resistance decades. Customized OEM solutions are also available, including for many other industries and future markets such as medical technology, biotechnology, and e-mobility. Many years of experience in the design and construction of measuring instruments and sensors ensure optimal solutions every time. Developed and manufactured in Germany, Burster sensors, amplifiers and transmitter modules, precision instruments, and measuring systems for sensor signal processing are shipped to customers worldwide.